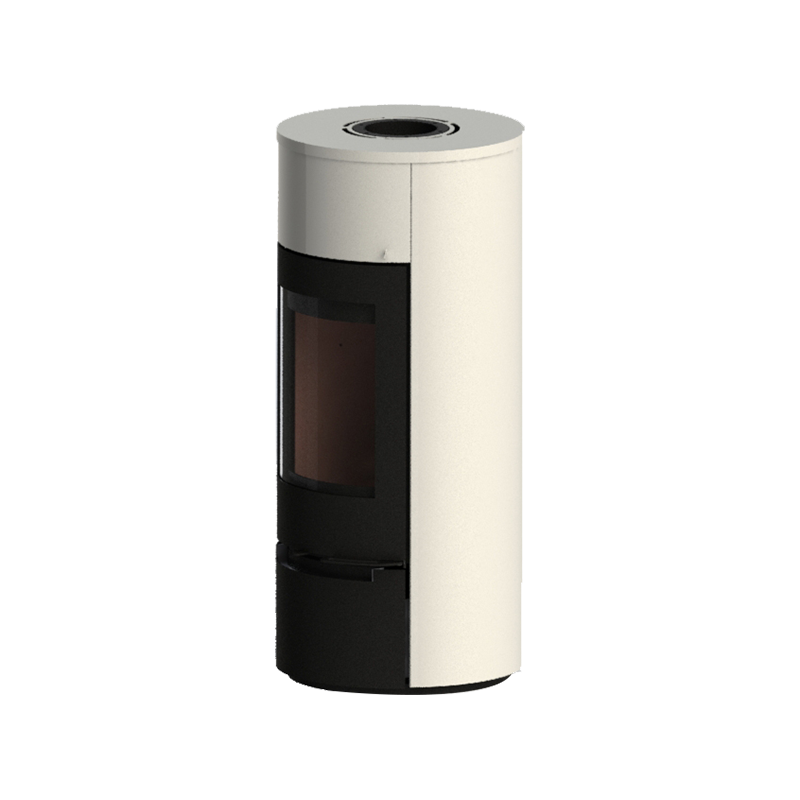

Round fireplaces have become an increasingly popular feature in modern home designs. Their unique shape, which contrasts with the more traditional rectangular fireboxes, adds an elegant touch to any room. However, like all fireplaces, maintaining their aesthetic appeal and ensuring their durability requires careful attention. One of the effective ways to enhance both the appearance and longevity of a round fireplace is through surface polishing treatment. This process not only improves the look of the fireplace but also ensures that it can withstand the wear and tear that comes with regular use.

In the context of round fireplaces, surface polishing can be applied to various components, including the firebox, mantel, surrounding frame, and even the hearth. Whether your fireplace is made from stone, stainless steel, or cast iron, surface polishing can bring out the material's natural beauty while also improving its performance.

There are several reasons why surface polishing is an essential step in maintaining the aesthetic and functional qualities of round fireplaces:

1. Improved Aesthetics

One of the primary reasons homeowners choose to polish their round fireplaces is to enhance the overall look. Over time, fireplaces can accumulate dirt, soot, and other residues that detract from their appearance. Polishing helps to restore the surface to its original luster, giving it a fresh, clean, and sleek look.

For example, stainless steel and cast iron, two common materials used in round fireplaces, benefit significantly from surface polishing. The process removes tarnishing and surface imperfections, allowing the metal to gleam and reflect light, adding a sophisticated, modern touch to the room.

2. Increased Durability and Longevity

Surface polishing treatment can also extend the lifespan of a fireplace. By smoothing out the surface, polishing helps prevent corrosion, rusting, and other forms of wear and tear. Fireplaces that are exposed to high temperatures, moisture, and the occasional exposure to harsh chemicals can degrade over time. Polishing removes scratches or abrasions that may cause materials to weaken, reducing the risk of structural damage.

In particular, materials like stainless steel and cast iron are prone to developing surface rust when exposed to moisture. Regular surface polishing helps prevent this issue by removing oxidation and applying a protective coating that resists rust formation, ultimately ensuring that the fireplace remains functional and safe for longer.

3. Enhanced Heat Distribution

While surface polishing is often associated with aesthetics, it can also contribute to the efficiency of the fireplace. For materials like stainless steel or cast iron, the smoother the surface, the more efficiently heat is distributed. A polished surface can allow the heat from the fire to radiate more evenly throughout the room, ensuring that the fireplace functions.

A smooth surface also allows for better airflow within the fireplace, enhancing the combustion process and allowing the fire to burn cleaner and more efficiently. This not only improves the performance of the fireplace but also contributes to energy efficiency, helping to reduce heating costs over time.

4. Easier Maintenance and Cleaning

A polished surface is much easier to clean than an untreated one. The smoother the surface, the less likely dust, soot, and grime will cling to it. This makes it easier for homeowners to maintain a pristine appearance for their round fireplace. For instance, cast iron and stone fireplaces that are regularly polished require less scrubbing and are less susceptible to stains or discoloration.

Moreover, polished surfaces are less likely to harbor bacteria or mold, which can thrive in rough, untreated areas. By choosing surface polishing treatment, homeowners can create a cleaner and more hygienic fireplace environment.